Laser Welding

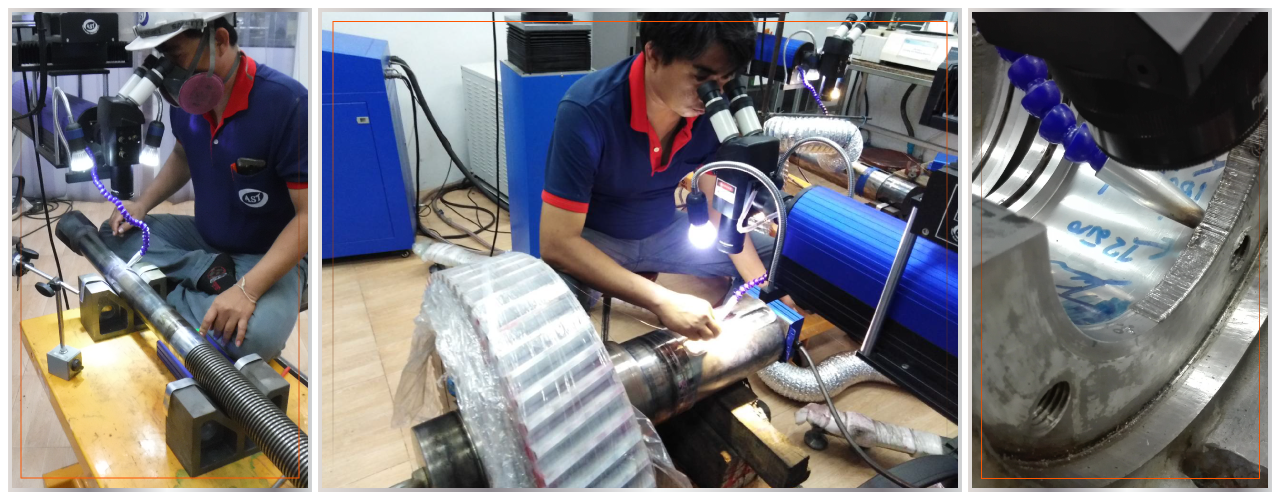

Our laser welding service is an advanced metallurgical process that utilises concentrated laser energy to melt and fuse materials with exceptional precision. This cutting-edge technique is perfectly suited for welding complex geometries and accessing narrow, deep areas.

We have optimised our equipment to deliver highly focused energy, ensuring the surrounding substrate remains unaffected. The localised temperature around the weld does not exceed 100°C, preserving the microstructure and preventing dilution of adjacent areas. Despite the intense precision, the weld quality remains unparalleled, offering strength and durability.

As our most efficient welding process, laser welding is available both on-site and at our facilities to suit your requirements.

![]()

- Reduces the heat exposure to the workpiece, minimizing changes in its structure, properties, or deformation, as the heat input is significantly lower compared to other welding methods.

- Faster, relative to other welding methods, as the smaller weld seam is more efficient in achieving surface finishing.

- Pre-heating is not required before welding.

- Extremely high precision.

- Exceptionally performance in welding narrow and deep areas of complex shaped work pieces.

![]()

We provide maintenance services for machine parts, both small and large, using laser welding techniques with surface finishing tailored to customer specifications. Our services cover a variety of industries, including petrochemical, power generation, mold manufacturing, and more. We offer a wide range of welding materials, such as Stainless 316L, Stainless 420, Duplex Stainless, and Stellite.